- Home

- High Purity Zinc Wires

ZINC WIRE

PRODUCT

SPECIFICATION

- TITLE: ZINC WIRE

- (99.995% Purity)

- PS:11

- ISSUE NO: 1

- REV. NO.:2

- DATE: 01.01.2012

REQUEST INFORMATION

SCOPE | PHYSICAL PROPERTIES | GENERAL | SAMPLING PLAN |

This Specification covers Zinc Wire majorly used fot Spray Metallization | Elongation: Above 40% | 1. Zinc Wires manufactured from Virgin Quality Special High Grande | One sample per 2,200 Lbs. lot. |

CHEMICAL COMPOSITION | ACCEPTANCE CRITERIA | SIZE ZINC WIRE HAVING SIZES | HANDLING AND STORAGE: – ZINC WIRE IS SUPPLIED IN |

(Conforming to IS- 12447, DIN 14919:2001, en 1179 Z1, ASTM B833-06) Zn: 99.995% (Min) | 1. Zin Wire should be free from Burrs, Cuts´s Kings, and Bends etc. | 0.0472 Inches to 0.2368 Inches with Tolerance of+0.00, -0.001969 inches | 1. 1,100 Lbs. Metal Drum |

SHELF - LIFE

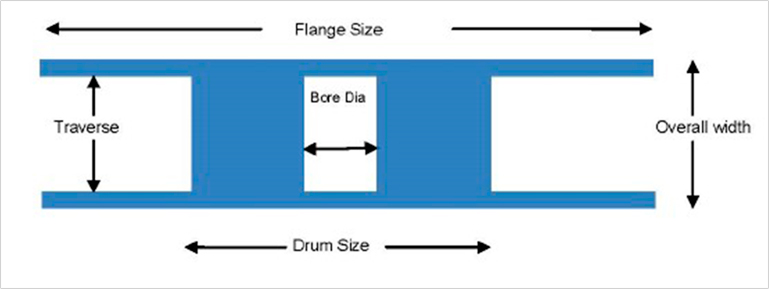

No | Type | Flange Size | Bore Dia. | Drum Size | Traverse | Overall Width | Capacity in Lbs. |

1 | KE 340 | 13.385″ | 2 1/21″ | 5.354″ | 4.763″ | 5 2/17 | 77 Lbs. |

2 | KE 300 | 11.811″ | 2.027″ | 8.346″ | 3.346″ | 3.858″ | 33.06 Lbs. |

3 | KE 270 | 10.629″ | 2.047″ | 5.826″ | 3.539″ | 4.055″ | 44.09 Lbs. |